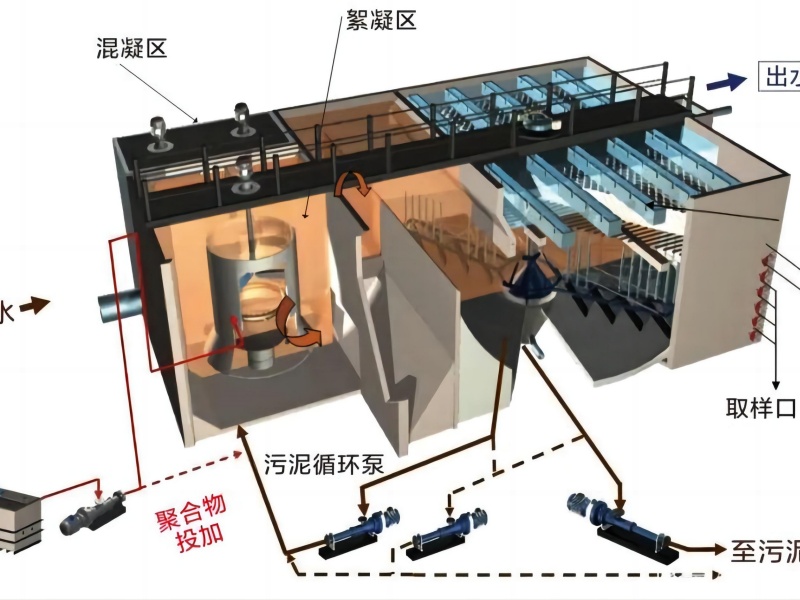

将污水通过沟渠自流引入集水池内,由取水泵将污水提升进入磁分离混凝系统,通过在混凝系统内投加磁种和混凝剂(PAC和PAM),使悬浮物在较短时间内(约4.5min)形成以磁种为载体的“微絮团”。混凝系统出水进入磁分离机将微絮团吸附打捞,进行固液分离净化,使其出水水质清澈透明,磁分离机出水达标排出。磁分离机分离出的磁种投加至混凝系统前段循环使用,非磁性就近排入污泥池,经污泥泵送入叠螺脱水机进行脱水处理,干泥输送至污泥箱,待运泥车外运处置。

Mobile Magnetic Separation Module

The wastewater is introduced into the collection pool through a channel by self-flow, and then pumped into the magnetic separation coagulation system by a lift pump. Magnetic seeds and coagulants (PAC and PAM) are added in the coagulation system, which allows suspended solids to form "micro-flocs" with magnetic seeds as carriers within a short period (approximately 4.5 minutes). The effluent from the coagulation system enters the magnetic separator where the micro-flocs are adsorbed and extracted, performing solid-liquid separation and purification, resulting in clear and transparent effluent that meets the discharge standards.

The magnetic seeds separated by the magnetic separator are recycled back to the front section of the coagulation system, while the non-magnetic substances are discharged nearby into the sludge pool. The sludge is then pumped into a decanter for dewatering treatment. The dewatered sludge is conveyed to a sludge box, awaiting transportation and disposal by sludge trucks.

18615687078

18615687078

全国服务热线

全国服务热线